You stand in a dealership parking lot on a crisp morning, keys in hand, torn between two nearly identical SUVs. One runs on gasoline. The other plugs into the wall. You’ve heard electric vehicles carry a heavy environmental burden at birth. You wonder if your choice truly matters.

Here’s what the science says: over its full lifetime, that electric SUV will produce 48 to 68 percent fewer greenhouse gas emissions than its gas-powered twin. The numbers don’t lie, and neither does the road ahead.

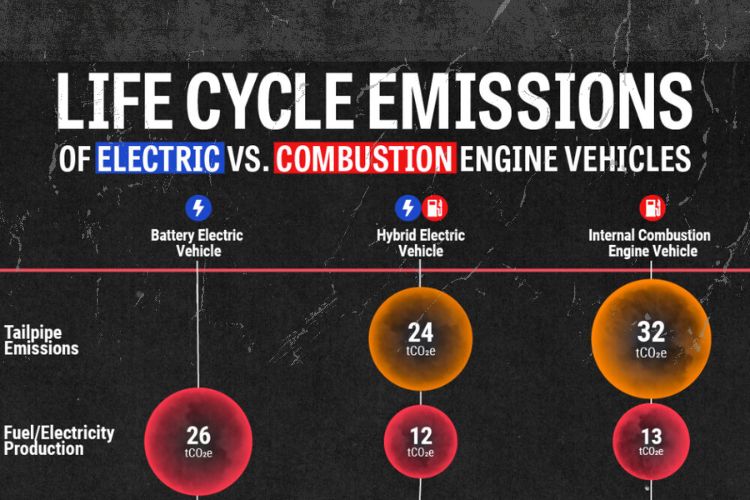

Keynote: Cradle to Grave EV vs ICE

Cradle-to-grave lifecycle analysis definitively shows battery electric vehicles produce 48-68% fewer emissions than gasoline cars across manufacturing, operation, and disposal phases. EVs offset their higher manufacturing footprint within 6-18 months of driving, then deliver compounding climate benefits throughout their 12-20 year lifespan as electricity grids progressively decarbonize.

The Full Story Your Car Doesn’t Tell You

You’ve been sold half the story for too long. Critics point to factory smokestacks and lithium mines. Advocates celebrate zero-emission badges on tailgates. Both miss the essential truth hiding in plain sight.

Every vehicle carries an invisible backpack of carbon from the moment raw materials leave the earth until the hulk hits the crusher. Mining cobalt for batteries or drilling crude for gasoline. Stamping steel in Michigan or assembling cells in Nevada. Every gallon burned or kilowatt drawn. The final journey to the scrapyard. This complete accounting, called lifecycle assessment, reveals which technology truly wins the climate race. And the verdict is clear.

What “Cradle to Grave” Actually Measures

Lifecycle assessment follows your car from birth to death. It starts deep underground where lithium brine pools shimmer in Chilean salt flats or oil rigs punch through shale. It tracks every ton of steel milled, every weld made, every battery cell sealed. Then comes the longest chapter: years of commutes, road trips, grocery runs. Finally, the crusher, the shredder, the recycling furnace.

Comparing only tailpipe emissions is like judging a book by chapter seven. You need the full story. A gas car spews visible exhaust. An electric car hums silently past. But both demanded energy and materials to exist. The difference lies in how much carbon each one drags through its entire journey.

Your personal story matters too. The grid powering your garage in Vermont runs on different fuel than one in West Virginia. A 12-mile daily commute writes a different emissions tale than 80 miles of highway. Battery size, driving style, even your local recycling infrastructure all shift the final tally. This isn’t about abstract national averages. It’s about your zip code, your habits, your actual life.

The Two Questions Keeping You Up at Night

Are electric vehicles genuinely greener when you count everything? Yes. Lifecycle studies from Argonne National Laboratory to the International Energy Agency converge on the same answer. Across 95 to 99 percent of scenarios worldwide, EVs emit dramatically less over their full lives.

Will your switch actually move the needle for the planet? More than you think. An electric pickup replacing a gas F-150 saves 74 tons of carbon dioxide over its lifetime. That’s equivalent to planting 1,700 trees and waiting 10 years for them to grow. One vehicle. One choice.

“I keep reading that EV batteries are worse for the environment than just burning gas,” a reader recently told me. “How can driving electric possibly help if it takes so much energy just to build the thing?” Fair question. Let’s dig into the numbers that answer it.

Manufacturing: Where Gas Cars Take an Early Lead

Building a Gas Car: The Devil You Know

Manufacturing a conventional vehicle follows a century-old playbook. Steel arrives at the plant. Robots weld frames. Workers bolt engines and transmissions into place. Glass goes in. Tires get mounted. Paint dries under heat lamps.

The process generates a predictable carbon footprint of roughly 10 tons of CO2 equivalent for a mid-size sedan. Factories have optimized every step over decades. No exotic minerals. No energy-intensive battery chemistry. Just steel, aluminum, glass, plastic, and a powertrain humans have built millions of times before. The emissions are known, mapped, and relatively consistent across manufacturers.

Traditional assembly relies on familiar supply chains and established recycling streams for metal. This maturity breeds efficiency. It also means there’s little room left for dramatic improvement. What you see is what you get.

Why EVs Start with a Carbon Debt

Electric vehicles enter the world carrying extra weight on their environmental ledger. Manufacturing a comparable EV generates approximately 15 tons of CO2 equivalent. That’s 50 percent more than a gas car.

The culprit sits under the floor: the battery pack. A 75-kilowatt-hour battery, common in mid-range EVs, accounts for 7.5 tons of manufacturing emissions by itself. That’s 40 to 60 percent of the entire production footprint packed into one component.

The gap widens with vehicle size. A short-range EV carrying a small 40-kWh battery adds only about 15 percent more manufacturing emissions than a gas equivalent. Scale up to a long-range SUV with a 100-kWh pack, and that penalty climbs to 68 percent. Bigger batteries deliver more miles per charge, but they also demand more upfront carbon.

Battery manufacturing creates between 59 and 115 kilograms of CO2 per kilowatt-hour today, depending on chemistry. NMC batteries (nickel-manganese-cobalt) sit at the higher end. LFP batteries (lithium iron phosphate) run cleaner at 54 to 69 kg per kWh. Industry targets aim for 20 kg per kWh by 2030 as factories shift to renewable power and processes improve. Even the current numbers beat what they were five years ago, and they’re dropping fast.

Inside the Battery’s Footprint

Lithium doesn’t jump from the ground into your battery. First, miners extract brine from underground aquifers in South America or crush spodumene ore in Australia. Processing lithium carbonate or lithium hydroxide requires heat, chemicals, and time.

Cobalt comes primarily from the Democratic Republic of Congo, often under conditions that deserve scrutiny. Nickel arrives from Indonesia, Russia, and Canada. Each mineral travels through refineries before reaching cathode manufacturers. Those cathodes get assembled into cells. Cells get packaged into modules. Modules become packs.

The most energy-hungry step happens in massive drying rooms where battery materials shed moisture under high heat for hours. Cathode production alone accounts for roughly 40 percent of battery manufacturing emissions. Factory location determines the carbon intensity of that energy. A plant in coal-heavy China produces batteries with 65 percent higher emissions than one in hydropower-rich Sweden.

Transportation contributes about 5 percent of the battery’s footprint. Not trivial, but far from the main driver. The real hotspots are mining, refining, and the energy-intensive production processes that turn raw minerals into precision-engineered power storage.

| Manufacturing Hotspot | Share of Battery Footprint | Emerging Solutions |

|---|---|---|

| Cathode Production | 40% | Renewable-powered factories, dry electrode coating |

| Mining & Refining | 25% | Direct lithium extraction, closed-loop water systems |

| Cell Manufacturing | 20% | Grid decarbonization, waste heat recovery |

| Pack Assembly | 10% | Lightweight designs, modular construction |

| Transportation | 5% | Regional supply chains, rail over truck |

On the Road: Where EVs Win Big

The Payback Moment Arrives Faster Than You Think

Every mile you drive in an EV erases a sliver of that manufacturing deficit. The math is simple: electric motors convert 77 to 91 percent of stored energy into motion. Gas engines manage only 12 to 30 percent. The rest vanishes as waste heat.

That efficiency gap translates to real-world emissions. An EV driving on the average U.S. grid produces about 223 grams of CO2 per mile. A comparable gas car emits 429 grams per mile. The difference compounds with every trip to work, every weekend errand, every vacation.

Battery electric vehicles typically erase their carbon debt within 6 to 18 months of normal driving. For most Americans, that breakeven arrives at 21,000 to 25,000 miles. Own the car for a typical 12 years and 150,000 miles, and you’ve stacked emissions savings far beyond that initial manufacturing penalty. After payback, every mile widens the environmental gap in your favor.

In regions blessed with clean grids like hydro-rich Quebec or wind-heavy Denmark, payback arrives in six months. Even in coal-heavy Poland, it takes just five years. And remember: that’s five years out of a 15-year lifespan. The math always swings toward electric eventually.

Lifetime Emissions: The Final Scoreboard

Let’s tally the full scorecard. A mid-size electric sedan driving 200,000 kilometers over 15 years on the average global grid produces approximately 25 tons of CO2 equivalent from cradle to grave. An identical gas sedan emits 54 tons. The EV wins by more than half.

In the United States, 2024 battery EVs emit 64 to 74 percent less than gasoline cars over their complete lives. A mid-size EV with an 84-mile range carries 15 percent higher manufacturing emissions but delivers 48 percent fewer total lifecycle emissions. In the European Union, where grids run cleaner and efficiency standards bite harder, BEVs average 73 percent lower emissions. Best-case scenarios in renewable-heavy regions exceed 80 percent reductions.

Electric pickups deliver the biggest single-vehicle climate impact you can make. Swapping a gas F-150 for an electric Lightning saves 74 tons of lifetime CO2. That’s not a rounding error. That’s the output of burning 8,300 gallons of gasoline.

| Vehicle Class | Gas Car Lifetime CO2 (tons) | Electric Car Lifetime CO2 (tons) | Emissions Reduction |

|---|---|---|---|

| Compact Sedan | 45 | 18 | 60% |

| Mid-Size Sedan | 54 | 25 | 54% |

| Mid-Size SUV | 65 | 30 | 54% |

| Full-Size Pickup | 85 | 40 | 53% |

Data assumes 200,000 km lifetime on average grid mix.

Why the Gap Keeps Growing

Here’s where the story takes a turn gas cars can’t follow. Electricity grids decarbonize yearly as utilities retire coal plants and add solar farms and wind turbines. Every year, the carbon intensity of the electrons flowing into your garage drops. Your 2025 EV automatically gets cleaner as the grid improves. No retrofit. No new parts. No action required.

A gas car burns the same carbon-dense fuel from year one until its last mile. Combustion chemistry doesn’t negotiate. An internal combustion engine built today will emit the same CO2 per gallon in 2040 as it does right now. It’s locked into its lifetime emissions profile the day it rolls off the assembly line.

After reaching the breakeven point, lifetime margins stretch to 50 to 75 percent savings depending on your grid. And that gap widens with every passing year as renewable energy scales. The EV you buy today will be cleaner tomorrow without you lifting a finger.

Your Grid Worries: Myth vs Math

“What If My Electricity Comes from Coal?”

Even the grimmest grid scenarios favor electric vehicles over their full lives. EVs outperform gas cars in 98 to 99 percent of U.S. counties, including those with coal-heavy electricity generation.

A BEV charged entirely on coal-fired power still emits less over its lifetime than a comparable gasoline vehicle. The reason is simple: power plants, even coal plants, convert fuel to electricity more efficiently than millions of tiny engines idling at red lights. Centralized generation beats distributed combustion every time.

As your state adds renewables, the same EV’s footprint shrinks automatically. No hardware changes. No service appointments. The car sitting in your driveway gets cleaner while you sleep because the grid behind the outlet improved.

The worst-case scenario for EVs is Poland, where coal dominates generation. Even there, lifecycle emissions for BEVs run 30 to 40 percent lower than gas cars. If it works in Poland, it works almost everywhere.

The Grid Can Handle It (Really)

Utility engineers lose sleep over air conditioners cranking on summer afternoons, not EVs charging overnight. Sufficient spare capacity exists during off-peak hours, especially between 10 p.m. and 6 a.m. when most EV owners plug in.

Smart charging systems reward you with lower electricity rates for charging when demand dips. They smooth out load curves and prevent strain on infrastructure. Some utilities pay you to let them manage charging timing automatically.

By 2030, Europe’s growing EV fleet could supply 4 percent of annual power needs back to the grid through vehicle-to-grid technology. That’s enough electricity to power 30 million homes during peak demand. Your car becomes a distributed battery stabilizing the grid, not stressing it.

“The grid collapse narrative is a myth,” says energy systems researcher Dr. Elena Verdolini. “We’ve integrated far more disruptive technologies like air conditioning without incident. EVs charge when the grid has capacity to spare.”

What Shifts Your Personal Payback

Your breakeven arrives faster if you drive in California than West Virginia. It comes quicker in a compact EV than a full-size SUV. City driving with regenerative braking beats constant 80-mph highway cruising.

Faster payback scenarios share common traits. Renewable-heavy grids cut charging emissions. Efficient models waste less energy. Right-sized batteries avoid manufacturing waste. Mostly city driving with gentle acceleration maximizes regenerative braking gains.

Slower payback hits if you live where coal dominates generation, choose an oversized SUV for a two-person household, or spend most miles at highway speeds above 75 mph. Even in these cases, you still break even within the vehicle’s expected life.

| Scenario | Effect on Payback | Example |

|---|---|---|

| Clean Grid (hydro, wind, solar) | Faster (6–12 months) | Pacific Northwest, Scandinavia |

| Mixed Grid (average U.S. mix) | Moderate (1–2 years) | Most of United States |

| Coal-Heavy Grid | Slower (3–5 years) | West Virginia, Poland |

| Right-Sized Battery | Faster | Compact EV for daily commute |

| Oversized Battery | Slower | 300-mile range for 20-mile commute |

| City Driving | Faster | Stop-and-go with regen braking |

| Highway Cruising | Slower | Constant 75+ mph speeds |

End of Life: The Second Act

When an EV Battery “Dies”

Automotive retirement doesn’t mean death for an EV battery. When capacity drops to 70 or 80 percent, it no longer delivers acceptable driving range. But it’s still perfectly capable of storing solar power for your home or stabilizing electricity grids.

Second-life applications extend battery usefulness by 15 to 20 years beyond automotive service. Companies extract battery packs from retired EVs and repurpose them for stationary storage. Your old Nissan Leaf battery might spend its golden years powering a rural clinic in Africa or smoothing renewable energy fluctuations in California.

Battery replacements are rare. Modern packs are warranted for eight years or 100,000 miles minimum, often far exceeding those guarantees. When replacement does occur, newer packs arrive cleaner to produce thanks to improving manufacturing processes. Many first-generation EV batteries will outlast the vehicles themselves.

Dead batteries aren’t landfill-bound. They’re profit centers packed with recoverable minerals worth hundreds of dollars per pack. Recyclers see gold mines, not garbage.

The Recycling Revolution Taking Shape

The global EV battery recycling market hit $3.88 billion in 2025. Analysts project $15.58 billion by 2030, representing 32 percent annual growth. This isn’t speculation. Recycling facilities are breaking ground across North America, Europe, and Asia right now.

Closed-loop systems reclaim lithium, cobalt, nickel, and other valuable materials for new battery production. This shrinks the footprint of next-generation packs by reducing demand for virgin mining. Three main recycling methods compete for dominance.

Pyrometallurgy involves smelting shredded battery material in furnaces at extreme heat. It recovers cobalt, nickel, and copper efficiently but burns off lithium and organic materials. It’s energy-intensive but works on any battery chemistry.

Hydrometallurgy dissolves battery materials in chemical baths, then selectively extracts and purifies each metal. This method recovers a wider range of materials including lithium at lower energy cost than smelting. Recovery rates top 95 percent for critical minerals.

Direct recycling refurbishes cathode materials without breaking them down to elemental components. It preserves the engineered crystal structure, dramatically cutting energy and emissions. This emerging approach could achieve true cathode-to-cathode recycling with minimal processing.

Current global lithium-ion battery recycling rates hover around 5 to 10 percent, but they’re climbing fast as first-generation EVs reach end of life and infrastructure scales. Europe leads with established collection networks and recycling mandates. By 2030, recycled materials could supply 20 to 30 percent of new battery production.

Gas Cars Aren’t Forever Either

Traditional vehicles also require end-of-life management. Engine oil, transmission fluid, coolant, and brake fluid all demand careful disposal to prevent environmental contamination. Exhaust systems contain catalytic converters with platinum group metals that need recovery.

The automotive recycling industry handles 80 to 90 percent of vehicle mass efficiently. Steel, aluminum, copper, and glass return to productive use. Automotive shredder residue, the mixed plastics and materials that can’t be easily separated, typically goes to landfills.

The key difference lies in material value. EV batteries hold recoverable materials worth recovering economically. Gas car fluids are disposal liabilities, not assets. Both vehicle types need responsible end-of-life handling, but the EV pathway offers stronger economic incentives for closing the loop.

| Material Stream | EV End-of-Life | ICE End-of-Life |

|---|---|---|

| Primary Valuable Material | Battery pack (lithium, cobalt, nickel) | Metal body (steel, aluminum) |

| Secondary Valuable Materials | Electric motor magnets (rare earths) | Catalytic converter (platinum group) |

| Disposal Liabilities | Coolant, brake fluid | Engine oil, transmission fluid, coolant |

| Recycling Economic Driver | High-value minerals | Bulk metal recovery |

| Circular Economy Potential | High (battery materials loop back) | Moderate (metals recycled, fluids disposed) |

Your Wallet’s Parallel Story

Ownership Costs Over Five Years

The climate story has a financial twin. Upfront EV prices have dropped dramatically as battery costs fall. Add the $7,500 federal tax credit, now available at the point of sale rather than waiting for tax season, and many EVs cost less than comparable gas cars before you drive off the lot.

Fuel savings stack up fast. Charging an EV for 15,000 miles yearly costs approximately $675 at average U.S. electricity rates. Filling a gas tank for the same distance runs $2,220 at recent fuel prices. That’s $1,545 in your pocket every year.

Maintenance tells an even better story. EVs cost 31 to 50 percent less to maintain. Average annual maintenance runs $330 for electric vehicles compared to $949 for gasoline vehicles. No oil changes. No transmission service. No exhaust system repairs. Regenerative braking extends brake pad life by years.

Total five-year savings range from $6,000 to $12,000 depending on driving habits, electricity rates, and local gas prices. Seven-year ownership pushes savings even higher as gas cars hit expensive maintenance milestones like transmission service and timing belt replacement.

| Cost Category | 5-Year EV Cost | 5-Year Gas Car Cost | Savings |

|---|---|---|---|

| Purchase Price (after $7,500 credit) | $32,500 | $35,000 | $2,500 |

| Fuel (15k miles/year) | $3,375 | $11,100 | $7,725 |

| Maintenance | $1,650 | $4,745 | $3,095 |

| Insurance | $6,500 | $6,000 | -$500 |

| Total 5-Year Cost | $44,025 | $56,845 | $12,820 |

Assumes average U.S. electricity and gas prices, typical maintenance schedules.

The Maintenance Simplicity Advantage

Pop the hood of an electric car and you’ll find empty space where complexity used to live. No pistons firing thousands of times per minute. No transmission shifting gears. No exhaust manifolds glowing red hot.

Electric motors have fewer than 20 moving parts. Gas engines have over 2,000. Fewer parts mean fewer failures. Fewer failures mean lower repair bills and less time waiting at the shop.

Software updates add features after purchase. Gas cars can’t download efficiency improvements or new driving modes. Your EV gets better as you own it. Your gas car slowly deteriorates from day one.

Federal Incentives You Can Actually Use

The Inflation Reduction Act restructured EV incentives to work at the dealership, not the tax office. Qualified new EVs receive up to $7,500 off the purchase price immediately. Used EVs built after 2019 qualify for up to $4,000.

Income caps apply: $300,000 for joint filers, $225,000 for heads of household, $150,000 for individuals. Vehicle price limits restrict new sedans to $55,000 MSRP and SUVs/trucks to $80,000. Used EVs must cost under $25,000.

Battery components must meet domestic content requirements that tighten yearly. Check the IRS qualified vehicle list before buying. Some states and utilities stack additional rebates on top of federal incentives, pushing total savings higher.

When Gas Cars Still Make Sense (Yes, Really)

Honest Scenarios Where ICE Wins

I won’t pretend electric works for everyone today. If you drive under 10,000 miles yearly in a coal-heavy state with no home charging option and limited public infrastructure, a used efficient gas car might generate lower lifetime emissions.

Frequent long-distance towing of heavy loads in extreme rural areas still favors gas or diesel. Current EV towing range drops significantly, and charger spacing in remote regions can’t support cross-country trailer hauling yet.

Budget constraints are real. Even with incentives, if upfront cost maxes out your financing and your apartment complex refuses to install charging, pragmatism wins. A reliable used gas car beats no car when you need transportation.

Your building’s unwillingness to add charging infrastructure creates a hard practical barrier. While public charging networks expand, daily reliance on them adds inconvenience and cost that undermines EV advantages.

The Hybrid Middle Ground

Plug-in hybrids split the difference with a gas engine for backup and a battery for daily electric driving. They emit more than pure EVs but far less than conventional gas cars if you charge regularly.

Lifecycle emissions for plug-in hybrids land around 39 tons, compared to 55 for gas cars and 25 for battery EVs on average grids. They work well for fence-sitters testing electric driving or those with charging access at home but long occasional trips.

Standard hybrids without plugs save fuel through regenerative braking and efficient engine operation but can’t drive on electricity alone. They cut emissions about 20 percent versus conventional gas cars. They’re a modest improvement, not a transformation.

| Powertrain Type | Lifetime Emissions (Average Grid) | Best Use Case |

|---|---|---|

| Gas (ICE) | 55 tons CO2e | Minimal driving, no charging access |

| Hybrid (HEV) | 47 tons CO2e | Moderate driving, no charging access |

| Plug-in Hybrid (PHEV) | 39 tons CO2e | Mixed short/long trips, home charging |

| Battery Electric (BEV) | 25 tons CO2e | Daily charging access available |

Your Real Life Trumps Generalizations

National averages don’t live your life. Your daily commute length matters more than EPA test cycles. Charging access at home or work changes the equation entirely. Local electricity sources shift the math.

Free online tools let you calculate your personal impact. The EPA’s Beyond Tailpipe Calculator and DOE’s Vehicle Cost Calculator accept your specific inputs: zip code, driving patterns, electricity rates, vehicle options. Spend 10 minutes with real numbers before deciding based on generic claims.

The “right” choice depends on your actual daily driving, not someone else’s ideal scenario. Be honest about your needs, generous about your future flexibility, and pragmatic about your current constraints.

What Nobody Tells You About Gas Cars

The Hidden Toll of Fuel

Upstream petroleum emissions hide in plain sight. Crude doesn’t teleport from the ground to your tank. Drilling, pumping, transporting, refining, and distributing gasoline carries a heavy lifelong footprint.

Refineries rank as the fourth-largest industrial source of U.S. greenhouse gas emissions. The process of cracking and reforming crude oil into gasoline releases CO2, methane, and other pollutants continuously. Then trucks deliver finished fuel to thousands of stations, each gallon hauled by diesel-burning transport.

“There’s a lot of focus on mining for battery materials, while nobody talks about petroleum’s social implications,” notes researcher Georg Bieker from the International Council on Clean Transportation. Oil extraction damages ecosystems through spills and wastewater. Refineries cluster in low-income communities, exposing residents to carcinogens and respiratory irritants.

Combustion’s unchangeable reality locks in every tank’s emissions permanently. Burn a gallon, emit 8.9 kg of CO2. Forever. No recovery. No recycling. Just atmospheric accumulation.

Beyond Carbon: Clean Air and Quiet Streets

Zero tailpipe emissions mean cleaner air in your neighborhood today, not decades from now. No nitrogen oxides causing smog. No particulate matter triggering asthma attacks. No benzene drifting into schoolyard lungs.

Cities switching to electric buses report measurable air quality improvements within months. Residents near charging stations don’t face health risks from refueling fumes. The benefits are local, immediate, and unequally distributed to communities that suffered most from traffic pollution historically.

Reduced engine noise creates more peaceful communities. Electric vehicles hum quietly past sleeping children instead of rattling windows. Conversation at sidewalk cafes doesn’t compete with acceleration roar. These quality-of-life improvements don’t show up in lifecycle emission charts, but they matter deeply to people living near busy roads.

Busting Myths That Cloud the Conversation

“EVs Are Dirtier to Make”—Let’s Clear the Air

True at the factory door. False over a full lifetime. This myth persists because it contains a kernel of truth wrapped in incomplete context.

Manufacturing a battery electric vehicle does create 15 to 68 percent more emissions than building a gas car. That gap narrows for smaller EVs and widens for large ones. Critics stop the story here.

The math tells the rest. Manufacturing deficit: 6 to 18 months of driving. Total lifespan: 12 to 20 years. After payback, every subsequent mile widens the emissions advantage in the EV’s favor. By year five, the gas car has emitted twice as much. By year 10, it’s not even close.

“Battery Mining Is Just as Bad as Oil”

Battery mineral supply chains need improvement. No sugarcoating that. Cobalt mining in the DRC involves child labor and environmental devastation. Lithium extraction in Chile stresses water resources. These problems are real, serious, and demand solutions.

The key difference: batteries get recycled and reused. Gasoline is burned once and gone forever. Mining impact is a solvable engineering and governance problem. Combustion physics aren’t negotiable.

Investment pours into ethical sourcing, less problematic chemistries like LFP that eliminate cobalt, and recycling that recovers 95-plus percent of materials. The industry is moving toward closed-loop systems. Oil extraction has no such pathway. It’s linear by nature: extract, refine, burn, repeat.

“What About Battery Replacement Costs?”

Modern batteries are warrantied for 100,000 to 200,000 miles minimum. Real-world data shows they’re exceeding expectations. A 2024 study of older Teslas found average capacity retention above 80 percent after 200,000 miles.

Degradation is gradual, not sudden. You lose range slowly over years, not catastrophically overnight. Many owners never replace batteries because the car’s body gives out first or technology advances make upgrading attractive.

When replacement does occur, costs have plummeted. Battery pack prices dropped 90 percent over the last decade and continue falling. By the time your 2025 EV might need a new pack, prices will be a fraction of today’s already declining costs. Many batteries get second lives in home storage rather than recycling, extending value further.

The Future Gets Greener

What 2030 Brings to Your Next Car Choice

Grids are adding renewable capacity at record pace. Solar and wind installations grew faster in 2024 than any previous year. Coal retirements accelerate. Your EV gets cleaner while parked in your driveway as the grid behind it transforms.

Battery technology improves continuously. Energy density increases mean smaller, lighter packs delivering the same range. Solid-state batteries promise even greater leaps in energy storage with lower manufacturing emissions. Production processes become more efficient as learning curves steepen.

Recycling infrastructure scales rapidly. The first wave of mass-market EVs sold in the 2010s reaches end of life this decade, feeding a growing stream of recyclable material back into new production. By 2030, recycled content could supply 20 to 30 percent of new battery demand, slashing mining needs.

| Technology | 2025 Status | 2030 Projection | Impact |

|---|---|---|---|

| Battery Cost | $115/kWh | $60/kWh | Lower vehicle prices |

| Grid Carbon Intensity (U.S.) | 390 g CO2/kWh | 240 g CO2/kWh | 38% cleaner charging |

| Recycled Content | 5-10% | 20-30% | Reduced mining pressure |

| Solid-State Batteries | Lab/prototype | Early commercial | Higher energy density |

Material Shortages: Squeeze or Ease?

Short-term lithium and cobalt constraints are driving innovation harder than abundance ever could. When materials cost more or supply tightens, engineers get creative fast.

Sodium-ion batteries use one of earth’s most abundant elements instead of lithium. They’re entering production now in China for stationary storage and budget EVs. LFP chemistry eliminates cobalt entirely while delivering acceptable performance for mainstream vehicles.

Solid-state batteries promise higher energy density with less material. Other chemistries under development reduce or eliminate rare-earth dependencies. The constraint is temporary. The innovation it sparks is permanent.

Recycling ramps up as first-generation EVs retire. Each retired battery feeds new production, progressively decoupling the industry from primary mining. By 2035, some analysts project recycled materials could meet the majority of battery demand for replacement production, with primary mining focused on fleet growth.

Quick-Reference Visuals

One-Glance Comparison

| Lifecycle Stage | Electric Vehicle (BEV) | Gas Vehicle (ICEV) | Notes |

|---|---|---|---|

| Manufacturing | 15 tons CO2e | 10 tons CO2e | Battery drives EV’s higher upfront footprint |

| Use Phase (150k miles) | 8 tons CO2e | 43 tons CO2e | Based on average U.S. grid mix |

| End of Life | 2 tons CO2e | 2 tons CO2e | Similar recycling processes for glider |

| Total Lifetime | 25 tons CO2e | 55 tons CO2e | 54% reduction for EV |

Sources: Argonne National Laboratory, IEA lifecycle assessments, ICCT analysis

“What Affects My Footprint Most?”

Three levers dominate your personal EV emissions profile more than everything else combined.

Grid Mix: The carbon intensity of your local electricity determines operational emissions completely. Charging in hydro-rich Washington State produces one-third the emissions of charging in coal-heavy West Virginia. Check your utility’s fuel mix disclosure.

Vehicle Size and Efficiency: A compact EV sedan creates 40 percent less lifetime emissions than a large electric SUV. Right-sizing your battery to actual needs avoids manufacturing waste. A 60-kWh pack for daily commuting beats a 100-kWh pack that sits mostly empty.

Battery Sourcing: Factory location matters. Batteries manufactured using renewable energy in Sweden generate 65 percent lower emissions than identical batteries made with coal power in certain Chinese provinces.

Action Checklist:

- Switch to your utility’s green electricity tariff if available

- Charge overnight when wind power typically peaks

- Match vehicle size to actual daily needs, not worst-case scenarios

- Maintain proper tire pressure for maximum efficiency

- Use regenerative braking aggressively in city driving

- Keep the vehicle longer to maximize payback benefits

Conclusion: You’re in the Driver’s Seat

From cradle to grave, electric vehicles have lower overall emissions in 95 to 99 percent of scenarios worldwide. The evidence doesn’t hedge. It doesn’t depend on future promises. It reflects today’s technology, today’s grids, today’s manufacturing.

For most Americans in most situations, EVs are environmentally superior. That’s not cheerleading. That’s the conclusion of Argonne National Laboratory, the International Energy Agency, the International Council on Clean Transportation, and every major lifecycle assessment conducted in the last five years.

Concerns about manufacturing emissions are valid but don’t change the final verdict. The initial carbon debt gets repaid quickly and overwhelmingly by superior operational efficiency. After that breakeven point, the environmental gap only widens.

Small Choices, Big Ripples

Match the car to your actual needs. Compact EV sedans have the smallest footprints. Buying a 300-mile range SUV for a 15-mile commute wastes battery capacity, manufacturing emissions, and money.

Charge on the cleanest power you can access. Solar panels on your roof deliver the lowest-carbon electrons. Green electricity tariffs from your utility cost pennies more monthly. Off-peak charging in wind-heavy regions taps cleaner power automatically.

Drive it longer. Maintain tire pressure. Use gentle acceleration. Accept software updates that improve efficiency. The environmental payoff from extending vehicle life by even two years exceeds the impact of most other green choices you’ll make.

You’re Part of a Bigger Solution

Every EV purchase votes for cleaner air and a stable climate with dollars, not just intentions. Your decision creates momentum that echoes far beyond your garage.

Infrastructure follows demand. Charging networks expand where EV adoption grows. Grids respond to load patterns by adding capacity strategically. Battery factories locate near demand centers. Your choice shapes the system.

This isn’t choosing blind anymore. You now have the full environmental story from mining through disposal. The data is clear. The choice is yours.

Life Cycle Emissions EV vs ICE (FAQs)

Do EVs really have lower lifetime emissions than gas cars?

Yes, definitively. Battery electric vehicles produce 48 to 68 percent fewer greenhouse gas emissions than comparable gasoline vehicles over their complete lifecycle in the vast majority of scenarios worldwide. This advantage holds true across 95 to 99 percent of global regions, including those with carbon-intensive electricity grids. The initial higher manufacturing emissions from battery production are offset within 6 to 18 months of typical driving, after which the EV delivers compounding environmental benefits for the remainder of its 12 to 20 year lifespan. Studies from Argonne National Laboratory, the International Energy Agency, and the International Council on Clean Transportation all converge on this conclusion using different methodologies and regional data.

How much CO2 is produced making EV batteries?

Current EV battery manufacturing generates between 59 and 115 kilograms of CO2 equivalent per kilowatt-hour of capacity, depending on the chemistry type and factory location. A typical 75-kWh battery pack produces approximately 7.5 tons of CO2 during manufacturing. NMC batteries (nickel-manganese-cobalt) sit at the higher end of this range, while LFP batteries (lithium iron phosphate) run cleaner at 54 to 69 kg per kWh.

Factory location dramatically affects these numbers because grid carbon intensity varies globally. Batteries manufactured in regions with clean electricity like Sweden or Quebec generate 65 percent lower emissions than identical batteries produced using coal-heavy grids. Industry targets aim to reduce battery production emissions to 20 kg CO2 per kWh by 2030 through factory decarbonization and process improvements.

When do EVs become cleaner than gas cars?

Battery electric vehicles typically become cleaner than comparable gasoline vehicles within 6 to 18 months of normal driving, or after approximately 21,000 to 25,000 miles. This breakeven point varies based on regional electricity grid composition, vehicle size, and driving patterns. In regions with renewable-heavy grids like the Pacific Northwest or Scandinavia, payback can arrive in as little as six months.

Even in coal-intensive regions like Poland, EVs reach carbon parity within five years. After this breakeven point, every additional mile driven widens the emissions gap in the EV’s favor. Over a typical 12-year, 150,000-mile lifespan, the cumulative emissions advantage becomes substantial, with EVs emitting 50 to 75 percent less than gas vehicles in total.

What’s the carbon footprint of lithium mining?

Lithium extraction contributes a relatively small portion of total battery manufacturing emissions, but it carries significant localized environmental impacts. Hard-rock mining in Australia is energy-intensive and can generate 3 to 5 tons of CO2 per ton of lithium carbonate produced, along with chemical pollution from processing.

Brine evaporation in South America’s Lithium Triangle is less energy-intensive but extremely water-intensive, consuming up to 500,000 liters of water per ton of lithium carbonate in arid regions. The total carbon footprint of lithium mining represents approximately 15 to 20 percent of overall battery manufacturing emissions. Emerging direct lithium extraction technologies promise to reduce both water consumption and energy requirements by 50 percent or more. Critically, lithium is a durable component that can be recycled repeatedly, unlike petroleum which is consumed permanently when burned.

How does electricity source affect EV emissions?

Electricity source is the single most influential variable in EV lifecycle emissions. An EV charged entirely on coal-fired electricity still produces lower lifetime emissions than a gas car but with a smaller advantage.

On a coal-heavy grid, EVs emit about 30 to 40 percent less than gas vehicles over their full lives. On the average U.S. grid mix, that advantage grows to 64 to 74 percent. On a 100 percent renewable grid powered by wind, solar, and hydro, EVs achieve 78 to 80 percent lower emissions than gas cars.

Importantly, as regional grids decarbonize by adding renewable sources and retiring fossil fuel plants, every EV automatically becomes cleaner without any hardware changes. This means an EV purchased today will have progressively lower operational emissions each year as the grid improves, while a gas car’s emissions remain fixed by combustion chemistry.