Picture your last car repair bill. Now imagine cutting it by 90%. That’s the reality electric vehicle owners experience every day. The numbers tell a stunning story: your gas car contains over 2,000 moving parts while an electric vehicle operates with just 20. It’s like comparing a Swiss watch to a simple desk fan.

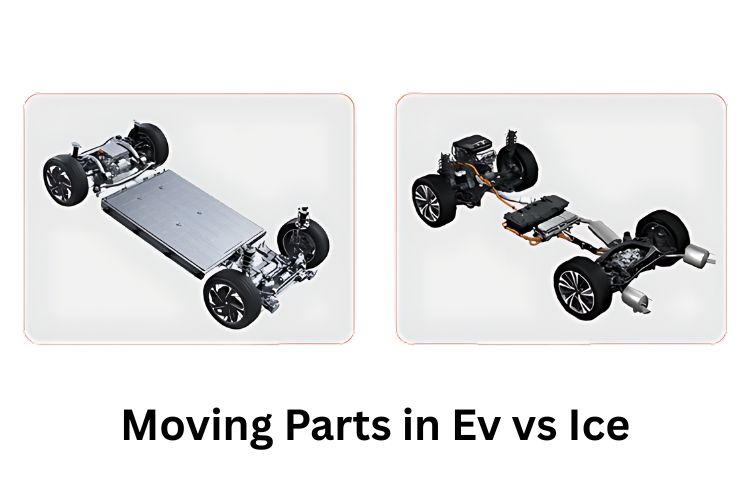

Keynote: Moving Parts In EV vs ICE

Electric vehicles contain just 20 moving parts versus 2,000+ in combustion engines, eliminating complex mechanical systems like pistons, valves, and multi-speed transmissions. This radical simplification reduces maintenance costs by 50%, improves reliability significantly, and delivers instant torque through direct electromagnetic energy conversion, creating fundamental ownership advantages.

The Numbers That Change Everything

The complexity gap between internal combustion engine vehicles and electric cars is staggering. ICE vehicles pack 200 to 2,000+ moving parts under the hood, each one a potential failure point waiting to happen. EVs glide by with just 20-30 moving parts total.

| Vehicle Type | Moving Parts Count | Primary Components |

|---|---|---|

| ICE Vehicle | 2,000+ | Engine, transmission, exhaust, fuel system |

| Electric Vehicle | 20-30 | Motor, battery, single-speed gearbox |

Every moving part in your ICE vehicle represents a maintenance schedule to track and a repair bill waiting to happen. Your bank account feels the difference every single month. I learned this truth the hard way with my last $3,000 transmission repair.

Why This Matters More Than You Think

This isn’t just about engineering elegance. It’s about your daily life. More moving parts mean more maintenance appointments, more unexpected breakdowns, and more money flowing out of your wallet. The 96% of EV owners who would buy electric again aren’t just satisfied with their purchase—they’ve escaped the mechanical complexity trap.

The ICE Engine: A Beautiful but Busy Orchestra

The Main Players Working Overtime

Your internal combustion engine operates like a violent symphony. Pistons pump thousands of times per minute like tiny hammers, absorbing the force of controlled explosions. Crankshafts and camshafts convert this chaotic motion into smooth rotation through perfect mechanical synchronization.

Valves open and close with split-second precision—16 to 32 valves in most engines, each one moving hundreds of times per minute. Timing belts keep this mechanical orchestra from becoming destructive chaos. When that single timing belt fails, pistons can collide with open valves, creating catastrophic damage worth thousands in repairs.

| ICE Engine Component | Count (4-cylinder) | Function |

|---|---|---|

| Pistons & Rings | 4 sets | Convert explosion force |

| Valves | 16 | Control air/fuel flow |

| Connecting Rods | 4 | Transfer piston motion |

| Camshafts | 2 | Operate valves |

The Hidden Supporting Cast You Forget About

The engine core cannot survive alone. It depends on multiple support systems, each containing their own failure-prone moving parts. Oil pumps circulate lifeblood through hundreds of friction points. Without this constant lubrication, metal surfaces would weld together in minutes.

Fuel injectors spray precisely measured doses of gasoline into each cylinder. These high-pressure components operate in harsh conditions and commonly fail. Spark plugs fire mini explosions constantly—over 1,000 times per minute at highway speeds. Water pumps battle the engine’s waste heat, which accounts for 68% of your fuel’s energy.

What This Complexity Really Costs

You’re maintaining a mechanical orchestra that never rests. Each of the 200+ parts follows its own maintenance schedule and carries its own price tag. The complexity creates a cascade of interdependence where one failed component can damage others, turning a simple repair into an expensive domino effect.

The EV Drivetrain: Elegant Simplicity That Just Works

Meet Your New Best Friend: The Electric Motor

The electric motor represents mechanical poetry. Just two main components create all the motion: a rotor that spins and a stator that stays still. No pistons hammering, no valves opening, no complex timing mechanisms requiring perfect synchronization.

This simplicity delivers instant power through non-contact electromagnetic forces. The rotor spins up to 15,000 RPM in whisper-quiet operation that feels almost magical. There’s no violent combustion, no waste heat requiring complex cooling systems, no need for thousands of precisely timed explosions.

“The beauty of an electric motor lies in its fundamental directness—electrical energy becomes rotational motion without the thermodynamic chaos of combustion,” notes powertrain engineer Sarah Mitchell.

The Complete Moving Parts List

Here’s the entire inventory of moving parts in most EV drivetrains:

- Electric motor rotor and shaft

- Motor bearings (2-4 total)

- Single-speed reduction gearbox gears

- Differential gears

- Coolant pump for battery thermal management

That’s genuinely the complete list. No reciprocating assemblies, no complex valvetrains, no multi-speed transmissions with hundreds of internal components. The absence of mechanical violence eliminates entire categories of wear and failure.

Why Fewer Parts Changes Your Daily Drive

Electric motors achieve 87-91% efficiency compared to ICE engines’ 20-30% efficiency. Less internal friction means components last longer and perform more predictably. The smooth, continuous power delivery feels like gliding rather than the controlled explosions your current car manages.

Instant torque from zero RPM eliminates the need for complex transmissions. While your gas car builds engine revolutions and shifts through multiple gears to reach peak power, an electric motor delivers maximum torque immediately.

The Money Talk: What This Means for Your Bank Account

Immediate Maintenance Savings

The numbers don’t lie about EV ownership costs. AAA data shows EV owners save $949 yearly on maintenance alone compared to similar ICE vehicles. You’ll never pay $35-75 every three months for oil changes again. Skip the $500-1,000 timing belt replacement every 60,000-100,000 miles.

Brake pads last 2-3 times longer thanks to regenerative braking, where the electric motor slows the car and recharges the battery simultaneously. Many EV owners report brake pads lasting over 100,000 miles compared to 30,000 miles in gas cars.

| Maintenance Item | ICE Vehicle Cost/Frequency | EV Equivalent |

|---|---|---|

| Oil Changes | $50 every 5,000 miles | None required |

| Timing Belt | $750 every 80,000 miles | No timing belt |

| Brake Pads | $300 every 30,000 miles | $300 every 100,000 miles |

| Transmission Service | $200 every 30,000 miles | Minimal gearbox service |

The Hidden ICE Costs Nobody Mentions

Transmission repairs devastate budgets when they fail unexpectedly. Complete rebuilds cost $3,000-4,000, turning a routine day into a financial crisis. Exhaust system repairs range from $200 for minor fixes to $2,000 for complete replacement.

The average ICE vehicle visits repair shops six times yearly compared to just two visits for EVs. That’s four fewer disruptions to your schedule, four fewer surprise repair bills, four fewer mornings dealing with tow trucks and rental cars.

Long-Term Reality Check

EVs save an average $4,600 over their vehicle lifetime in maintenance costs alone. Add fuel savings of $1,000+ yearly, and total ownership savings reach $10,000-14,000 over 15 years. Consumer Reports confirms EV owners pay approximately half as much for maintenance and repairs as comparable ICE vehicle owners.

| Cost Category | 5-Year ICE Total | 5-Year EV Total | Savings |

|---|---|---|---|

| Maintenance | $4,745 | $2,400 | $2,345 |

| Fuel/Energy | $7,500 | $3,500 | $4,000 |

| Major Repairs | $2,200 | $800 | $1,400 |

| Total | $14,445 | $6,700 | $7,745 |

The Shared Parts Story: What Both Cars Still Need

Yes, Some Things Stay the Same

Both vehicle types require tires, suspension components, and steering systems that age similarly. Windows, wipers, and cabin air filters follow comparable replacement schedules. However, even these shared components often last longer in EVs due to gentler operating conditions and less vibration.

The absence of engine vibration reduces stress on suspension mounts and body panels. No hot exhaust system means less thermal cycling damage to nearby components. The smooth, quiet operation creates a more stable environment for all vehicle systems.

The Regenerative Braking Advantage

Regenerative braking transforms energy waste into efficiency gains. When you lift off the accelerator or press the brake pedal gently, the electric motor reverses its role and becomes a generator. This process captures kinetic energy that would otherwise become waste heat in friction brakes.

The result extends brake component life dramatically. Brake pads barely work during most driving because the motor handles deceleration. Less brake dust means cleaner wheels and improved air quality around your vehicle.

“I haven’t changed brake pads in 80,000 miles,” reports Tesla Model S owner Mike Chen. “The regenerative braking handles probably 80% of my stopping needs.”

Busting the “But EVs Are Complex!” Myth

Addressing Your Valid Concerns

EVs do contain sophisticated battery management systems and advanced power electronics. The complexity exists, but it’s electronic rather than mechanical. Software and solid-state components replace mechanical assemblies prone to physical wear.

Electronic parts don’t experience the friction, heat cycling, and mechanical stress that destroy ICE components. Power switches operate millions of cycles without degradation. Battery management systems monitor thousands of parameters but contain no moving parts to wear out.

| Complexity Type | ICE Vehicle | Electric Vehicle |

|---|---|---|

| Mechanical | Very High | Very Low |

| Electronic | Moderate | High |

| Failure Mode | Wear/Friction | Software/Electronic |

| Repair Complexity | Physical parts | Module replacement |

The Battery Question Everyone Asks

Modern lithium-ion batteries consistently outlast their 8-10 year warranties. Real-world data shows gradual capacity degradation of just 1.8% annually, not sudden failure. Most EVs reach 200,000 miles before needing significant battery work.

Battery replacement costs have dropped 89% since 2010 and continue falling. Many EV batteries retain 80% capacity after 200,000 miles, still providing adequate range for daily driving. The gradual degradation process gives owners years to plan for eventual replacement.

Real Stories from the Road

“I Saved $3,000 in Two Years!”

Sarah Williams switched to a Model 3 after her Honda Accord’s third transmission issue in five years. “I was spending $1,800 yearly on maintenance and repairs,” she explains. “Now it’s maybe $400 for tire rotations and cabin air filters. The relief of not worrying about breakdowns is honestly priceless.”

Her charging costs average $45 monthly compared to $180 for gasoline. The combination of lower fuel and maintenance costs puts an extra $200 monthly in her budget.

“Charging at Home Changed Everything”

Mike Rodriguez charges his Nissan Leaf overnight like plugging in his phone. He skips gas station detours completely, saving 30 minutes weekly plus $200 monthly on fuel. “I never realized how much time I spent at gas stations until I stopped going,” he notes.

The convenience extends beyond time savings. No more fuel price anxiety, no more detours when running late, no more standing in weather pumping gas. Home charging transforms the ownership experience from reactive to proactive.

Your Next Move: Making the Switch Make Sense

Three Questions to Ask Yourself Right Now

How much did you spend on car repairs last year? Add up the oil changes, unexpected breakdowns, and that major repair that hurt your budget. Most people underestimate their true automotive maintenance costs until they calculate the annual total.

When did your car last surprise you with a breakdown? ICE vehicles develop problems without warning. Timing belts snap, transmissions fail, cooling systems leak. The mechanical complexity creates unpredictable failure patterns that disrupt your life and budget.

Could you use an extra $1,000+ in your pocket yearly? The maintenance savings alone justify consideration, but combined with fuel savings, the financial impact becomes compelling for most households.

Starting Your Research

Test drive an EV to experience the smooth, quiet difference firsthand. The instant torque and silent operation feel dramatically different from ICE acceleration. Many people discover the driving experience itself justifies the switch.

Calculate your personal savings using online tools from manufacturers and energy companies. Input your current fuel and maintenance costs to see realistic projections. Check charging options at your home and workplace to understand your daily routine changes.

Compare warranty coverage between EV and ICE options. Electric powertrains typically receive longer warranties because manufacturers understand their superior reliability. Battery warranties often extend 8-10 years compared to 3-5 years for ICE powertrains.

Research Checklist:

- Test drive similar EV and ICE models back-to-back

- Calculate charging costs vs. fuel costs for your driving

- Assess home charging installation requirements

- Compare total warranty coverage

- Research local service center availability

The Bottom Line

The mechanical simplicity of EVs isn’t just an engineering achievement—it’s a practical revolution that touches every aspect of ownership. Fewer moving parts create a cascade of benefits: higher reliability, lower costs, better performance, and superior efficiency.

The technology has matured beyond early adoption. Real-world data from millions of EVs proves the reliability advantage translates into genuine financial benefits and reduced ownership stress.

Conclusion

The 96% of EV owners who would buy electric again aren’t just satisfied customers—they’ve experienced the liberation of mechanical simplicity. They’ve discovered that fewer moving parts don’t just mean lower maintenance costs; they mean freedom from the constant worry of mechanical failure.

The numbers speak clearly: 20 moving parts versus 2,000 isn’t just a statistic. It’s the difference between a reliable appliance and a complex mechanical puzzle that requires constant attention. Your future self will thank you for making the switch to simplicity.

Number of Parts in EV vs ICE (FAQs)

How many moving parts does an electric car have?

Electric vehicles contain approximately 20-30 moving parts in their drivetrain, primarily consisting of the motor rotor, bearings, and simple reduction gearbox components. This contrasts sharply with internal combustion engines that contain 200-2,000+ moving parts including pistons, valves, crankshafts, and complex multi-speed transmissions.

What maintenance do EVs not need?

EVs eliminate most traditional maintenance requirements including oil changes, timing belt replacements, spark plug changes, fuel filter replacements, exhaust system repairs, transmission services, and cooling system maintenance. The absence of combustion eliminates the need for managing heat, friction, and combustion byproducts that require constant attention in gas vehicles.

Why are EVs mechanically simpler?

EVs achieve mechanical simplicity because electric motors produce rotational motion directly through electromagnetic forces, eliminating the need to convert explosive energy into rotation like combustion engines. This direct energy conversion removes entire mechanical systems: no reciprocating pistons, complex valvetrains, multi-speed transmissions, or exhaust systems are needed.

Do electric cars have transmissions?

Most electric cars use single-speed reduction gearboxes rather than traditional multi-speed transmissions. Electric motors provide maximum torque from zero RPM and operate efficiently across a wide speed range, eliminating the need for gear changes. This single-speed system contains far fewer parts than conventional automatic transmissions with their hundreds of gears, clutches, and hydraulic components.