You know that feeling when your phone battery hits 20% and suddenly every decision revolves around finding a charger? That’s exactly how I felt about EVs until recently. But something remarkable is happening under the hood of electric cars right now—a complete reimagining of what batteries can do.

We’re not talking about minor tweaks here. I’m talking about batteries that charge faster than you can grab coffee, last longer than you’ll own the car, and cost less than today’s gas-guzzler alternatives. The best part? Some of these breakthroughs are already hitting the road, while others are closer than you think.

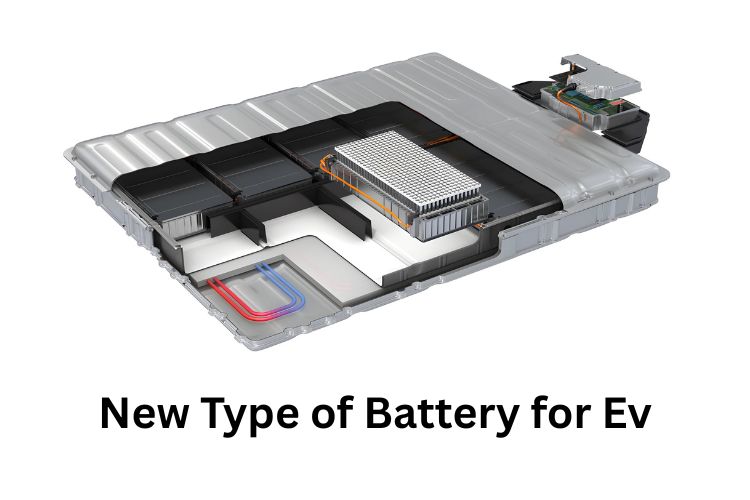

Keynote: New Type of Battery for EV

Revolutionary EV battery technologies are reshaping electric mobility in 2025. Solid-state batteries promise 50% more range with 10-minute charging. Sodium-ion cells enable $25,000 EVs through abundant materials. Silicon anodes boost current batteries 20-50%. Multiple chemistries will serve different market segments, not single replacement technology.

Why Your Current EV Battery Feels Like Yesterday’s Tech

The Triple Threat of Today’s Battery Blues

Range anxiety turns every road trip into a strategic puzzle. Charging sessions eat 30-45 minutes of your precious time. Replacement costs between $5,000-$20,000 make your wallet weep. Cold weather performance drops range by up to 40%.

These problems stem from fundamental trade-offs in lithium-ion technology. The dominant NMC batteries deliver 200-350 Wh/kg energy density but rely on expensive cobalt and nickel. LFP batteries cost less and last longer but sacrifice energy density at 160-200 Wh/kg. You’re forced to choose between range, cost, safety, and longevity.

What “New Battery Tech” Actually Means for You

Chemistry changes fundamentally alter how energy gets stored. Instead of shuffling lithium ions between traditional electrodes, new approaches use different materials entirely. Architecture shifts squeeze more power into the same space through cell-to-pack integration. Smart systems adapt to your driving patterns in real-time, optimizing performance automatically.

The breakthrough lies in moving beyond the constraints of liquid electrolytes, graphite anodes, and cobalt-dependent cathodes. These new technologies promise to eliminate the compromises that define today’s EV ownership experience.

| Battery Type | Energy Density (Wh/kg) | Cycle Life | Cost ($/kWh) | Key Advantage |

|---|---|---|---|---|

| NMC (Current) | 200-350 | 1,000-2,000 | $85-90 | High energy density |

| LFP (Current) | 160-200 | 3,000+ | $65-75 | Low cost, safety |

| Solid-State (Future) | 350-450 | 8,000-10,000 | $120-150 | Ultimate performance |

| Sodium-Ion (Now) | 75-160 | 3,000+ | $45-55 | Ultra-low cost |

Solid-State Batteries: Your “Never Worry Again” Solution

Why Engineers Call This the Holy Grail

Zero liquid electrolyte equals zero fire risk. Imagine the relief of never worrying about thermal runaway or battery fires. The solid ceramic or polymer electrolyte creates an impenetrable barrier that makes catastrophic failure virtually impossible.

50% more energy gets crammed into the same footprint. By replacing bulky graphite anodes with thin lithium metal, solid-state cells achieve 350-450 Wh/kg. That translates directly to 50-75% more range without adding weight or size to your vehicle.

8,000-10,000 charge cycles versus today’s measly 1,500-2,000 means the battery outlasts the car itself. You could charge daily for 25 years without meaningful degradation.

What This Means for Your Monday Morning Commute

Charge to 80% in under 10 minutes at any fast station. The stable lithium metal interface enables charging rates that seemed impossible with liquid electrolytes. Drive from New York to Chicago without a single charging stop—600+ mile ranges become routine rather than exceptional.

Extreme weather becomes irrelevant. Full performance at negative 40°F or 120°F eliminates seasonal range anxiety completely. The solid electrolyte maintains ionic conductivity across temperature extremes that cripple today’s batteries.

Reality Check: When You’ll Actually Drive One

Toyota commits to pilot production late this decade, with limited volumes targeting 2027-2028. BMW and Hyundai follow closely with 2028-2029 targets for premium models. Manufacturing challenges keep pushing commercial dates, but progress is accelerating.

QuantumScape recently powered a motorcycle with its solid-state cells, proving real-world viability. Solid Power delivers prototype cells to BMW and Ford for vehicle testing. The technology works—scaling production remains the bottleneck.

Sodium-Ion: The People’s Champion That Changes Everything

Finally, Batteries Made from Table Salt (Yes, Really)

Sodium is 1,000 times more abundant than lithium. No more supply chain panic over rare materials concentrated in geopolitically sensitive regions. Zero dependency on conflict minerals or cobalt mining creates a completely ethical supply chain.

Expected 20-40% cost reduction makes EVs truly mainstream. CATL’s sodium-ion cells already cost 30% less than LFP batteries. This isn’t theoretical—it’s happening in production vehicles right now.

Perfect for Your Real Life, Not Just Road Trip Dreams

Lower energy density proves completely fine for 95% of your driving. Most people travel less than 50 miles daily, making 200-300 mile sodium-ion ranges perfectly adequate. Superior cold-weather performance eliminates winter range anxiety that plagues LFP batteries.

CATL and BYD already ship these in actual cars you can buy. Chinese automakers offer sodium-ion city cars starting under $10,000. The technology moved from labs to showrooms faster than anyone predicted.

The Hybrid Solution Nobody’s Talking About

Combine sodium for daily drives with lithium for long-haul capability. CATL’s “Freevoy” packs blend both chemistries in one system. Smart battery management switches between them automatically based on driving conditions and temperature.

This hybrid approach could make $25,000 EVs profitable by 2026. Use cheap sodium-ion for 80% of driving, reserve expensive lithium for occasional long trips. It’s brilliant engineering that solves real-world problems.

The Speed Demons: Fast-Charging Breakthroughs Already Here

CATL’s Qilin Battery: 478km in 10 Minutes (Not a Typo)

4C-5C charging rates feel like science fiction but aren’t. The new cell structure handles extreme power without overheating or degradation. Real-world translation: 300 miles while you grab a sandwich and use the restroom.

Advanced thermal management enables this performance. Liquid cooling channels run directly through the cell structure, not just around the outside. Heat dissipates instantly, preventing the thermal buildup that limits today’s fast charging.

Silicon Anodes: The Instant Upgrade Happening Now

Replace graphite with silicon for 20-50% more range immediately. Silicon stores ten times more lithium ions than graphite, directly boosting energy capacity. Tesla and GM actively test silicon-enhanced anodes in current production cells.

This represents a drop-in replacement that works with existing infrastructure. No new charging standards or manufacturing overhauls required. Around 30% of EV battery anodes already contain some silicon content.

The Grid Reality Nobody Mentions

Your local charging station might be the bottleneck, not the battery. Many DC fast chargers max out at 150kW, limiting actual charging speeds regardless of battery capability. Infrastructure upgrades race to catch up with battery capabilities.

Home charging remains king for daily use. Level 2 charging overnight handles 95% of driving needs. Fast charging matters for road trips, but home convenience drives daily satisfaction.

LMFP and Other Quiet Game-Changers Flying Under the Radar

Lithium-Manganese-Iron-Phosphate (LMFP): The Goldilocks Battery

Higher voltage than LFP, better safety than NMC. LMFP delivers 15-20% energy density improvement over standard LFP without using expensive nickel or cobalt. It operates at 4.1 volts versus LFP’s 3.2 volts, enabling more energy in the same cell size.

Already moving from labs to manufacturing lines. Chinese battery makers lead development, with pilot production beginning in 2024. This chemistry offers the sweet spot between cost, performance, and safety that automakers desperately seek.

Cell-to-Pack Architecture: More Power, Same Space

Eliminates modules entirely—think removing unnecessary packaging. Traditional battery packs waste 20-30% of volume on module casings and connectors. Cell-to-pack design fits 10-15% more energy in the same space.

BYD’s Blade battery pioneered this approach. Long, thin cells mount directly to the pack structure, creating a simpler, lighter, and more efficient system. Tesla’s 4680 cells follow similar principles.

| Architecture Type | Energy Density Gain | Weight Reduction | Cost Impact |

|---|---|---|---|

| Traditional Module-to-Pack | Baseline | Baseline | Baseline |

| Cell-to-Pack | +10-15% | -15-20% | -10-15% |

| Cell-to-Body | +20-25% | -25-30% | -20-25% |

Your Personal Battery Timeline: What to Expect When

Available Right Now (Yes, Today)

LFP batteries in Tesla Model 3 offer 272,000+ mile lifespans. Fast-charging capable packs reach 80% in 18 minutes at peak power stations. 300+ mile ranges become standard, not premium features.

Current technology already solves most practical concerns. Today’s EVs handle daily driving better than many people realize. The question isn’t whether they work—it’s whether the next generation will be dramatically better.

Coming 2025-2027: The Near-Future Sweet Spot

Silicon-anode batteries debut in premium models first. Expect 20-30% range improvements in flagship vehicles from Mercedes, BMW, and Lucid. Mass-market sodium-ion EVs launch under $30,000, targeting urban commuters.

400+ mile ranges become boring, not exceptional. LMFP adoption in mainstream models balances cost and performance. The charging infrastructure expands to support higher power levels nationwide.

The 2028-2030 Revolution

First solid-state vehicles hit dealer lots in limited quantities. 10-minute charging becomes standard expectation rather than luxury feature. EV prices match gas cars without subsidies through manufacturing scale and material innovation.

Battery longevity exceeds vehicle life, creating robust second-life markets. Grid storage applications absorb retired EV batteries, improving renewable energy integration.

The Problems Nobody Talks About (But Should)

Manufacturing Reality Checks

Solid-state production requires completely new factories. Current lithium-ion manufacturing equipment cannot produce solid electrolytes. Building new gigafactories takes 3-5 years minimum, explaining delayed commercialization timelines.

Quality control challenges delay mass production. Solid electrolytes must be perfectly uniform across large areas—any defect creates a failure point. Current lab-scale success doesn’t guarantee factory-scale reliability.

The Hidden Technical Hurdles

Solid electrolytes crack under repeated stress. Thermal expansion and contraction during charging cycles creates mechanical stress. Interface compatibility between new materials remains tricky—different expansion rates cause delamination.

Room temperature performance still needs optimization. Many solid electrolytes work well at elevated temperatures but struggle at freezing conditions. Automotive applications demand all-weather reliability.

Why Your Current EV Isn’t Suddenly Worthless

Today’s lithium-ion technology improves 5-7% annually through incremental advances. Software updates extend range and performance in existing vehicles. Robust used EV markets develop regardless of future technology advances.

Current batteries already last longer than most people keep cars. Even older EV technology provides reliable service for 8-10 years minimum.

Making Your Move: The Buyer’s Real-World Guide

If You Need an EV in the Next 12 Months

Focus on proven LFP or enhanced NMC options. Look for 300+ mile range as your baseline—anything less feels limiting on longer trips. Prioritize manufacturers with strong charging networks like Tesla’s Supercharger access.

Consider total cost of ownership, not just purchase price. LFP vehicles may cost slightly more upfront but save thousands in longevity and reduced degradation over time.

If You Can Wait 2-3 Years

Watch for silicon-anode announcements from major brands. Consider sodium-ion for budget-conscious city driving needs. LMFP models will offer the best balance of everything—performance, cost, safety, and longevity.

The 2026-2027 model years represent a sweet spot. Most next-generation improvements arrive without the premium pricing of initial launches.

The Charging Infrastructure Question That Actually Matters

Home charging capability remains priority number one. Level 2 charging overnight handles 95% of driving scenarios. Fast-charging coverage along your regular routes matters more than absolute charging speed.

Future-proofing means 800V architecture compatibility. Higher voltage systems enable faster charging as infrastructure upgrades. Look for vehicles supporting 350kW+ charging rates.

Beyond Cars: How These Batteries Transform Everything

Your Home as a Power Station

Vehicle-to-grid technology makes your EV a mobile generator. During power outages, your car’s battery powers essential home systems for days. Seamless integration with solar panels creates complete energy independence.

Potential to earn money feeding power back during peak demand. Utilities pay premium rates for grid storage during high-demand periods. Your parked EV becomes a revenue-generating asset.

The Recycling Revolution Already Starting

“Battery passports” track materials from birth to rebirth. Digital records enable 95% material recovery through advanced recycling processes. Second-life applications power entire neighborhoods using retired EV batteries.

Closed-loop recycling infrastructure develops rapidly. New battery plants increasingly co-locate with recycling facilities, creating circular supply chains that reduce raw material dependency.

Conclusion: Your Electric Future Is Closer Than You Think

I get it—the constant stream of battery breakthrough news can feel overwhelming. But here’s what really matters: the barriers that kept you from considering an EV are crumbling faster than ever. Whether it’s the solid-state revolution promising worry-free road trips, sodium-ion making EVs affordable for everyone, or the silicon upgrades happening right now, each innovation solves a real problem you face today.

The question isn’t whether to go electric anymore—it’s simply which wave of innovation you want to ride. And honestly? Even today’s “old” technology is pretty incredible. The future isn’t just coming; parts of it are already parked in driveways. Maybe it’s time yours was one of them.

New Type of EV Battery (FAQs)

When will solid state batteries be available for electric cars?

Limited production solid-state EVs will likely debut between 2027-2028 in premium vehicles from Toyota, BMW, and Mercedes-Benz. Mass market availability remains at least 5-7 years away due to manufacturing scaling challenges. Current prototypes work well, but building gigafactory-scale production requires completely new manufacturing processes and equipment.

What battery will replace lithium ion in EVs?

No single technology will replace lithium-ion entirely. Instead, different chemistries will serve specific market segments: sodium-ion for affordable city cars, LMFP for mainstream vehicles, solid-state for premium models, and enhanced lithium-ion for performance applications. The future is multi-chemistry, not replacement.

How much range do silicon anode batteries add?

Silicon anodes can increase range by 20-50% compared to traditional graphite anodes. Tesla and other manufacturers already incorporate small amounts of silicon in production batteries. Full silicon anodes could boost energy density from today’s 250-300 Wh/kg to 400+ Wh/kg, translating to 400-500+ mile ranges in typical EVs.

Which automakers are using LFP batteries 2025?

Tesla uses LFP in standard-range Model 3 and Model Y vehicles globally. Ford offers LFP in Mustang Mach-E base models. Chinese automakers BYD, NIO, and XPeng use LFP extensively. GM and Stellantis plan LFP adoption for affordable EV models launching 2025-2026.

Why are sodium ion batteries cheaper than lithium?

Sodium is over 1,000 times more abundant than lithium and can be extracted from seawater or common salt. This eliminates supply chain constraints and price volatility associated with lithium mining. Manufacturing processes are similar to lithium-ion, but raw materials cost 40-60% less. No expensive cobalt or nickel required, further reducing costs.